|

| August 06, 2019 | Volume 15 Issue 29 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Partnership rises to cool challenge using best-kept secret in the circuit breaker industry

Modular parallel compressor rack units eliminate the need for mechanical rooms.

The global retail sector has grown during the last few years, and the United States is leading the pack. Specifically, the demand for ready-to-eat products has increased, bringing with it additional demand for commercial refrigeration. This demand for refrigeration can be seen in places such as supermarket display cases, industrial ice-making machines, walk-in coolers, reach-in coolers, and chillers.

Sawyer's Food Supply is a fast-growing food supplier in the Bahamas that supplies its own supermarkets, as well as other local markets on the island. In 2017, Sawyer's began construction on a new refrigerated warehouse that was 20 times the size of their previous building. With a much larger area to refrigerate, the power demand would skyrocket. Combine this with the overall higher electricity costs associated with being located on an island and Sawyer‘s Food Supply owner, Sandy Sawyer, knew that reducing energy consumption would be a key part of ensuring a return on the company's investment.

Challenge

In December 2017, FriconUSA was commissioned by Sawyer's to retrofit the entire refrigeration system. FriconUSA is an exciting new player in the commercial refrigeration industry. They have recently received UL certification and have jumped into the nascent U.S. market. Well-established for over 25 years in Venezuela as FRITECH, FriconUSA was launched in 2000 outside of Atlanta, GA, and specializes in air-cooled chillers, condensing units, and industrial ice-makers, among others.

For this project, FriconUSA approached NOARK with their design challenge: create a flexible product, control costs, reduce energy consumption, and deploy it all very quickly. As an additional challenge to this project, the isolation clearance and raceways used for wiring and maintenance would require designing a modification to raise the mounting plate in order to comply with NEC code. In order to reach all these goals, FriconUSA and Sawyer's Food Supply would need to consider every component in this project and their impact on the ROI.

Results

In late 2016, FriconUSA established a partnership with low-voltage component manufacturer NOARK Electric. NOARK is a fairly new player in the U.S. industrial automation market with UL-certified components and an industry focus on the heating, air conditioning, and refrigeration equipment markets. Through this partnership, FriconUSA has incorporated many NOARK molded case circuit breakers and motor control components, such as contactors, relays, and starters, into their designs. Working closely together, the FriconUSA engineering team and NOARK local and overseas support teams selected components that would meet the project challenges.

Says Fernando Escuela, president and founder of FriconUSA, "NOARK and FriconUSA work well together. They have a solid, high-performance product line. They also have local support to assist our operation, including application and technical support."

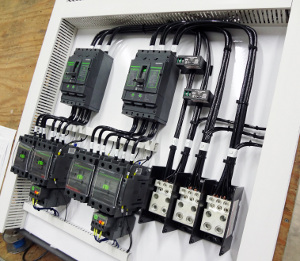

After reviewing the project needs, the NOARK Ex9M series UL 489 molded case circuit breakers and the Ex9C contactors were determined to be the ideal fit. B1N miniature circuit breakers were used in the power circuit control design, while NOARK Ex9C contactors were utilized in the system's motor control and protection scheme. A safe, UL508-compliant motor control circuit protection scheme was created that met all standards and each of the end-user's requirements -- including a 20 percent reduction in energy consumption. In addition, FriconUSA and NOARK teams were able to develop a modification to ensure that all NEC codes were met.

The Bottom Line

With the new modular refrigeration system by FriconUSA, the project is underway and in operation, as of mid-2018. Further expansion will follow, with plans to open 10 more Sawyer's Fresh Market supermarkets at the rate of two per year.

FriconUSA's highly efficient solution for the refrigerated warehouses and new supermarkets includes expanded scope to integrate a photovoltaic solar plant and a clean energy system to generate the electricity to further increase Sawyer's overall energy savings. By working closely with their key partners to leverage their support, FriconUSA was able to meet the challenge and deliver a successful solution on budget and on schedule.

As for NOARK Electric and FriconUSA, they plan many more projects for collaboration in the future.

Maritza Barrios, marketing coordinator and sales associate at FriconUSA, says, "In this evolving HVAC/R market, NOARK offers high-tech products that can fit into our sometimes challenging custom applications. We always appreciate the attention to detail and the resources brought to support us for technical problems that might arise."

Ed Joe, marketing director for NOARK Electric North America, concurs. "Every customer assumes you have a reliable, quality product offering -- that's the baseline," he says. "It's the extra effort that it takes to come through during a customer's time of need that counts most. Our greatest asset is our local, knowledgeable field team and the support they can provide."

About FriconUSA

Located just north of Atlanta, FriconUSA manufactures high-quality and efficient icemakers, air-cooled chillers, modular chillers, and industrial condensing units for the food retail, commercial, and industrial refrigeration and air conditioning sectors. FriconUSA recently entered the U.S. market after over 20 successful years in Venezuela, working hand-in-hand with distributors to ensure the best project development for their clients.

https://www.friconusa.com/

About NOARK

NOARK Electric is a global supplier of low-voltage electrical components for specialty manufacturing industries. They strive to provide their customers with high-quality products at an affordable price, backed by a five-year limited warranty. They are committed to becoming a leader in cost-effective components through the development of innovative products and continuous improvements, while demonstrating integrity, trust, and honesty.

For more information, contact Ed Joe, marketing director, Noark Electric (North America), 2188 Pomona Blvd., Pomona, CA 91768. Phone: 779-771-8881. Email ed.joe@noark-electric.com. Website na.noark-electric.com.

Source: NOARK Electric

Published August 2019

Rate this article

View our terms of use and privacy policy